This was every bit an informative talk laced with some quite challenging mathematical concepts which inform on best bridge design.

Computational modelling and optimisation are able to predict how a bridge’s components and structures will behave under specific conditions, and thereby improving design, efficiency and manufacturing technique e.g. with 3D printing

What are the span limits for any bridge form?

Beams

For example, those made from stone have a very limited span. Steel fares a bit better. So what alternative forms are more efficient and allow for a greater span?

Arches

Robert Hooke 1635-1703 investigated the shape of an arch by hanging weights from a straight beam. He then inverted this shape to deduce the optimal arch shape for efficient bridge construction.

Forces generated by the weight of a stone arch bridge limit span to just 120m.

Other materials e.g. reinforced concrete or metal can extend that limit to around 400m.The steel rail bridge at Newcastle upon Tyne would be a good example.

Fig 1 Types of arches

Cable supported

The most usual form is the suspension bridge, for example the Humber Bridge

The main towers were built first and linked together with a pair of cables spun each side of the bridge and vertical cables hanging down to support the deck. Deck sections were then made to complete it. It was opened 40 years ago and was the inspiration for Dr Gilbert’s future career in civil engineering on a school trip.

Other examples are the planned Halsafjorden in Norway which will span 2050m. Wind engineering aspects are important with a bridge of this size, with wind tunnel aerodynamic testing, wind buffeting, flutter and vortex induced vibration leading to ongoing modification of the bridge deck geometry. There will be a floating tower in the middle anchored to the fjord bed below.

The span of a simple suspension bridge is the distance of suspended roadway between towers and the 2km span of the Akashi Kaikyõ Bridge in Japan is the limit.

Cable-stayed form

Long span arches need cable-stays. Cables directly connect the towers to the roadway by a series of diagonal stays between tower and deck. This bridge form is efficient as the main construction steps are simultaneous. The main tower with progressive lateral deck extension on each side increases the span. Deck extensions then meet and are joined together.

The Queensferry Forth Replacement Crossing is a 4-span cable-stayed bridge with main spans of 650m

Hybrid suspension and cable-stayed bridges are even more efficient. Diagonal cables are dropped to support the deck

while being extended. The middle part is supported by main cables. The longest bridge in the world, 164.8km long, is the hybrid Danyang Kunshan Grand Bridge in China

The best form of bridge

The most important question is the optimal minimal volume of material required to build the most resilient structure. As bridge span increases, progressively more of the structure is necessary to simply carry its own weight, thereby limiting the span.

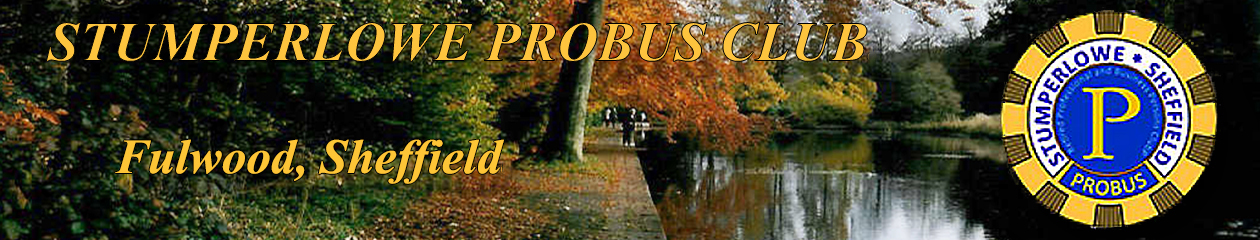

Steel currently is the material of choice, so the only alternative at present is to adapt the efficiency of bridge design. A simple bracket with an attached weight is a good analogy. A large difference in volume is achieved using an orthogonal bracket shape (Fig 5).

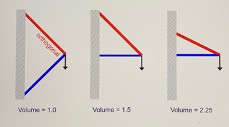

Computer modelling has shown that complex orthogonal layouts are best for achieving equilibrium of bridge structure (Fig 6).

But not all tension and compression elements are orthogonal because the weight of the structure itself needs to be factored in.

Development of the ideal is ongoing. There are economic issues, and factors such as wind loading and materials; when substitution of steel by carbon graphene becomes technically feasible, the app Layopt.com (“try it yourself”) suggests the possibility of a 10 km span.

Most of the forces on a bridge are directed down the tower. A new bridge form needs less material largely because the forces from the deck are transmitted from the superstructure to the foundations. This is achieved by keeping load paths short and maintaining wide angles between the tensile and compressive elements. Sharp angles give large compression forces. Changing the compression/tension ratio optimises change in shape and type of bridge

A bridge too far

A bridge has been proposed to link the UK with Ireland. Bridge length is a bigger problem further south between Wales and Eire. Scotland on the other hand adds to journey time from England and the continent. There are considerable financial, structural and political challenges but it is feasible. A combined tunnel bridge would be possible.